Rốt cuộc thì bộ trao đổi nhiệt là gì? Đó là một thiết bị được sử dụng để chuyển nhiệt từ chất lỏng này sang chất lỏng khác. Các ngành công nghiệp thực phẩm hoặc dược phẩm và các nhà sản xuất hóa chất cần sử dụng bộ trao đổi nhiệt hàng ngày. Đây là những công cụ rất hữu ích để làm nóng hoặc làm lạnh chất lỏng mà không mất năng lượng. Điều này khiến chúng rất hữu ích để tiết kiệm tiền và thân thiện với môi trường bằng cách tiêu thụ ít điện hơn.

Các công việc khác nhau yêu cầu tăng hoặc giảm nhiệt độ bằng bộ trao đổi nhiệt. Trong lĩnh vực chế biến thực phẩm, ví dụ như bộ trao đổi nhiệt được sử dụng để làm lạnh quá mức sữa sau khi đã qua tiệt trùng. Điều này đặc biệt quan trọng, vì nếu sữa nguội quá chậm, nó có thể bị hỏng. Không ai muốn uống sữa đã bị hỏng! Ứng dụng của bộ trao đổi nhiệt Được sử dụng để làm mát và ngưng tụ khí thành chất lỏng trong các nhà máy hóa dầu. Ví dụ, một số khí có thể gây hại nếu chúng quá nóng. Việc làm mát chúng một cách hiệu quả là rất quan trọng vì chúng có thể gây ra tai nạn cũng như đảm bảo an toàn cho người lao động.

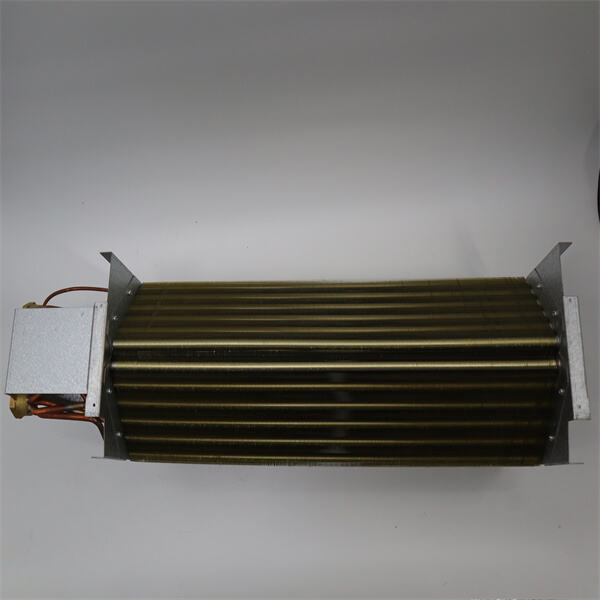

Máy trao đổi nhiệt, do được thiết kế để hoạt động trong điều kiện khắc nghiệt nên những máy móc này phải thực sự mạnh mẽ và vững chắc. Orbcomm cho biết một số máy được đặt trên giàn khoan dầu ngoài biển, nơi chúng phải chịu đựng nước muối và gió mạnh. Nhiều môi trường này rất khắc nghiệt đối với thiết bị, vì vậy máy trao đổi nhiệt phải được xây dựng bền bỉ để chịu đựng chúng. Một số máy trao đổi nhiệt khác hoạt động trong các nhà máy hóa học, nơi chúng xử lý các chất ăn mòn và thậm chí là nguy hiểm. Những máy trao đổi nhiệt này được làm từ vật liệu robust và chống mài mòn để xử lý các nhiệm vụ khó khăn này.

Các công ty đôi khi cần thiết bị trao đổi nhiệt ngoài phạm vi thông thường vì yêu cầu của họ khác với những người khác. Đó là lúc một thiết bị trao đổi nhiệt tùy chỉnh được sử dụng. Chính những thiết kế độc đáo như vậy đáp ứng được nhu cầu của một công ty. Ví dụ, một thiết bị trao đổi nhiệt nhỏ có thể được chế tạo để lắp đặt trong không gian hẹp nếu đó là điều công ty cần. Nó đặc biệt hữu ích hơn khi có hạn chế về không gian. Hoặc, nếu một công ty cần một thiết bị có thể chịu đựng được các chất lỏng ăn mòn có khả năng làm hỏng các máy móc tiêu chuẩn, thì nó có thể được chế tạo từ vật liệu cứng cáp không bị hòa tan. Nhờ cách này, thiết bị trao đổi nhiệt có thể thực hiện công việc của mình một cách chính xác và hiệu quả.

Hơn nữa, chúng cũng được sử dụng để bảo vệ máy móc và vật liệu. Chúng loại bỏ nhiệt bằng nước sau đó trở thành hơi nước trong các nhà máy điện. Nó có thể làm hỏng máy móc sản xuất điện, thứ mà tất cả chúng ta cần mỗi ngày. Công ty lưu ý rằng bộ trao đổi nhiệt được sử dụng trong ngành công nghiệp hóa học, ví dụ như để làm mát khí. Khí không được làm mát đúng cách cũng có thể làm hỏng các bộ phận quan trọng, đòi hỏi sửa chữa đắt tiền và gây ra nguy hiểm về an toàn.