Factories need to be cold! And don't waste your $ if you do! If the temperature rises causes it to occur, this can damage machines and reduce productivity if not rectified. This can lead to increased production times and costs. The reason is why gas cooler heat exchangers are so cool! Things stay chill in the factories as it keeps everything cool.

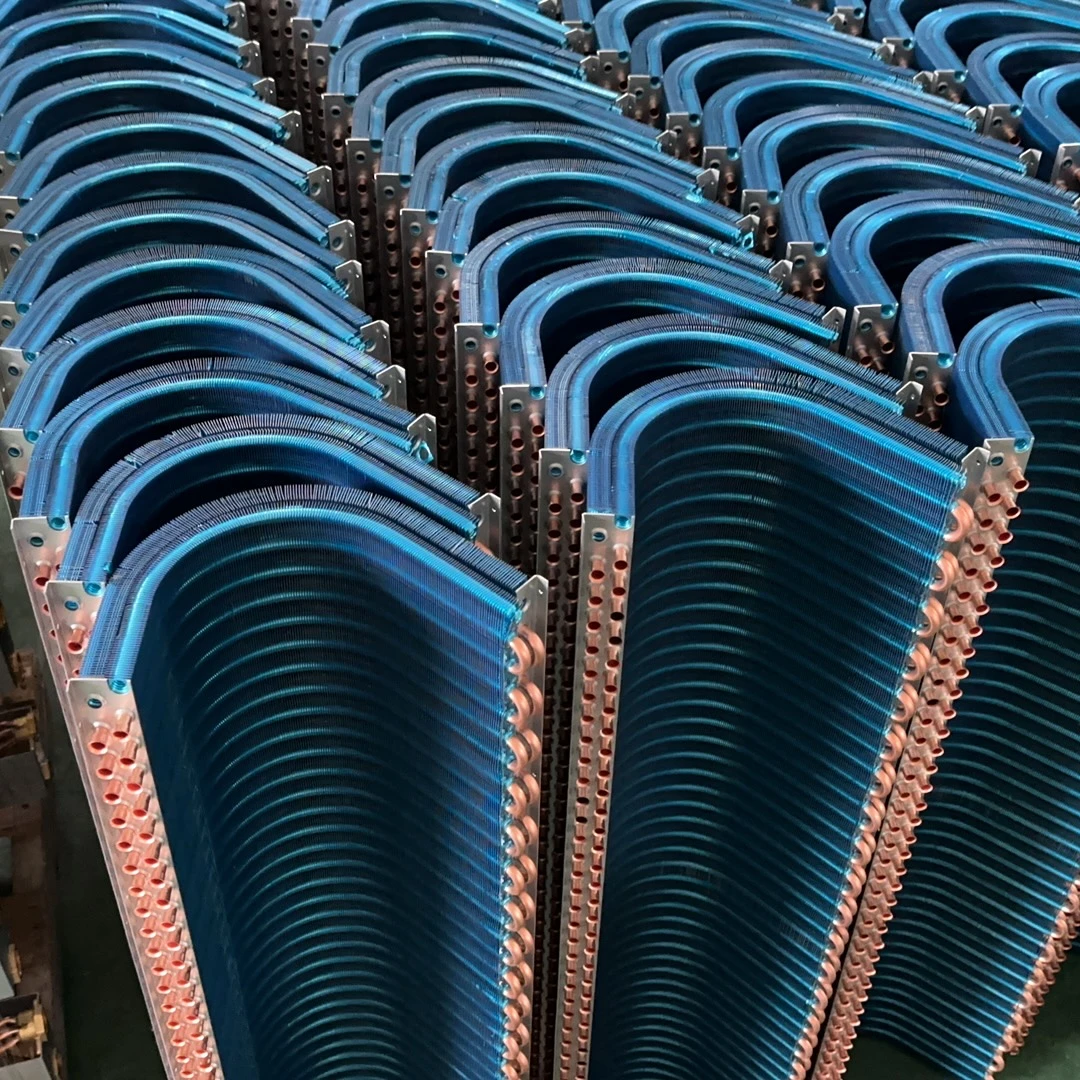

Gas cooler heat exchangersPass gas through special tubes that are in contact with cool water or air. Because of this, it cools down the gas: stealing some its heat. After that the gas was re-cooled and reused to this factory — perfect waste management! Not saving anything, the re-circulation simply reduces energy-consumption over venting this greenhouse-gas to space. This will allow shells to be used for gas again on factories, so that it can run smoothly with an eye of the environmental factors.

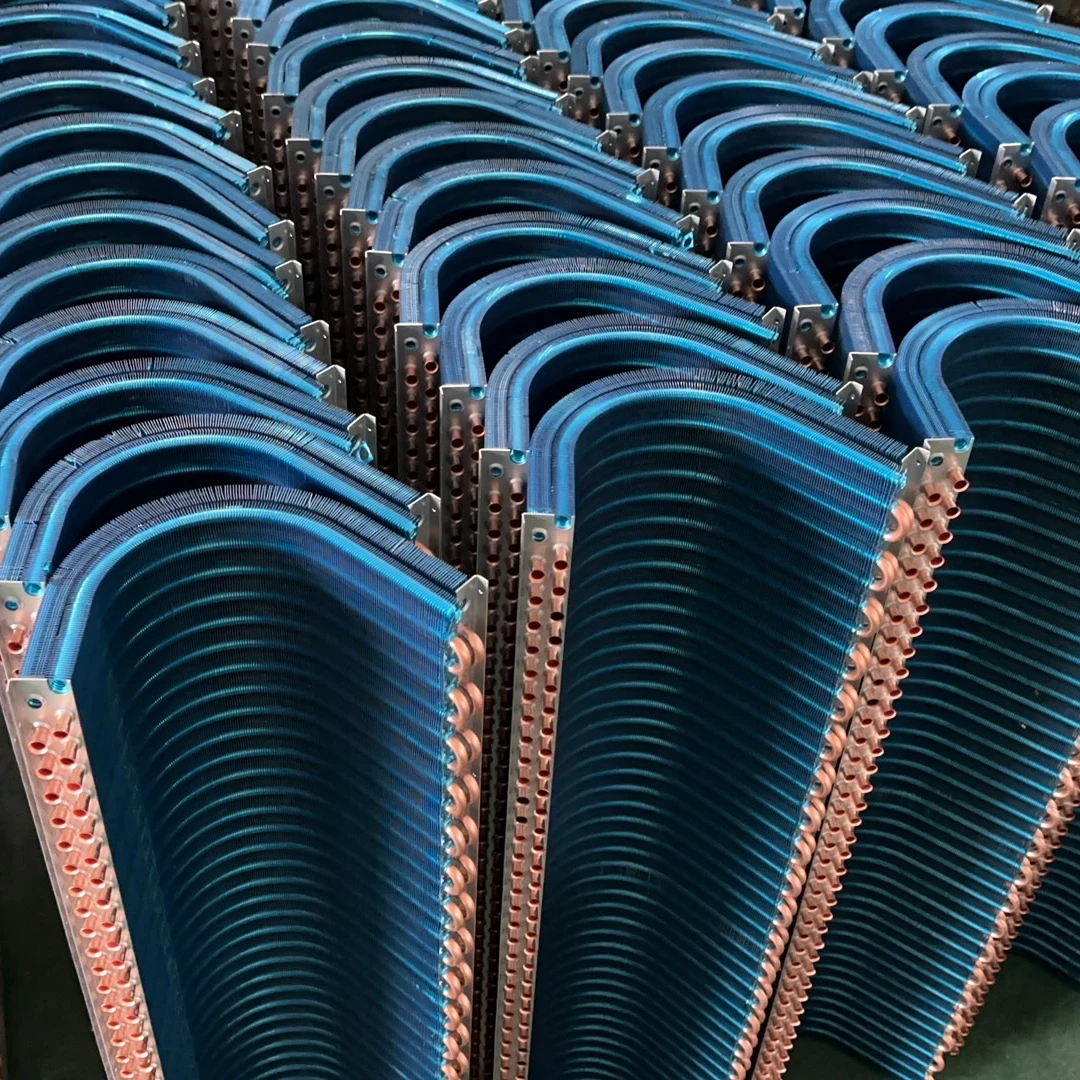

Heat Exchangers (That just sounds cool)- These allow substances to combine and release heat staying at a low temperature. They are also used in applications such as air conditioning, power plants and refrigerants. Many industrial processes rely on such heat exchangers in avoiding the excess of temperature. Cool gas → Gas cooler heat exchangers All in all, this cools gas to below 100 degrees Celsius which is better for most factory purposes and will not actually break any of the workers machines.

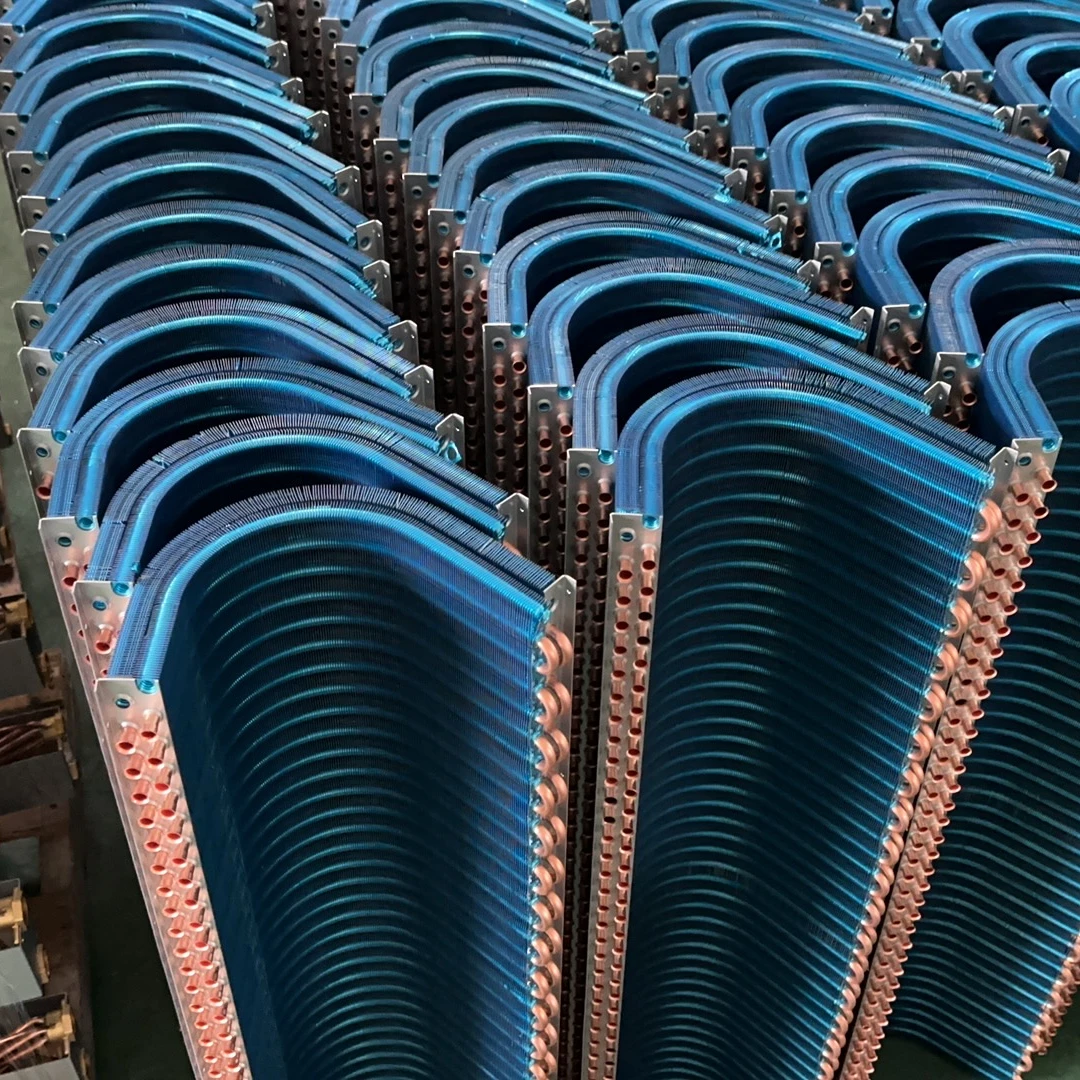

A Gas Cooler heat exchanger is perfect for cooling gas. As a result of their creation to withstand excessive temperatures and stress, these rubber seals create superb products or services with regard to the hardest factory settings. These are also small and compact, which makes them easy to place in most existing factory set up without hogging large area or even need substantial changes for the current machinery.

Gas cooler heat exchangersThe registered designs are affordable, do what they say on the tin and tend to work well enough in practice. Thus you would not require to pay a great deal of mending and maintenance. Because they are long lasting and can last you many years without having to replace them with short intervals.

If thus gas cooler heat exchanger is one of the later technologies that has been published since quite long time ago but yet there are still many owners ignoring this technology which benefits they can use and then save more. They also recycling wasteful gas mit would only come out of a void in the air so you will not have to purchase new lotuaran what. II By having everyone charged all those, it saves you money for your factory and that is just a too big deal It also, of course, contributes to a reduction in pollution via recycling.

It also help to improve the efficiency in your factory. This cooling of the gas prevents harm for machines consequently spare repair cost. These machines can perform more efficiently which means that you will be able to get even a lot done but in less time without heating up your equipment.

offerings include heat exchangers well as air gas cooler heat exchanger indoor units. also offer air conditioning systems. products suitable many different scenarios such commercial, industrial bathrooms kitchens.

salesconsultants rich experiences both after-sales pre-sales. They'll quick responds any inquiries have, gas cooler heat exchanger items require in shortest periods time, offers competitive transactions prices industry.

gas cooler heat exchanger uses 3D design as well heat transfer simulations, among techniques help every customer with equipment design matching maximize efficiency. offer deep customization accordance with needs customers requirements, offering single-stop solution starting scratch performing turnkey projects.

SHUANGJUN Electric Appliance gas cooler heat exchanger. established 2007 grown into reputable company specialized production refrigeration equipment. constant development progress over last two decades, have become leading machine manufacturer solution supplier HVAC Refrigeration industry.