The aluminum heat exchangers they make use of are unique because the tools that help in transferring towns from one place to another. These are crafted from a soft metals, typically aluminium; it is very workable and can be molded into many shapes. These features make aluminium a vague option for several kind of heat exchangers.

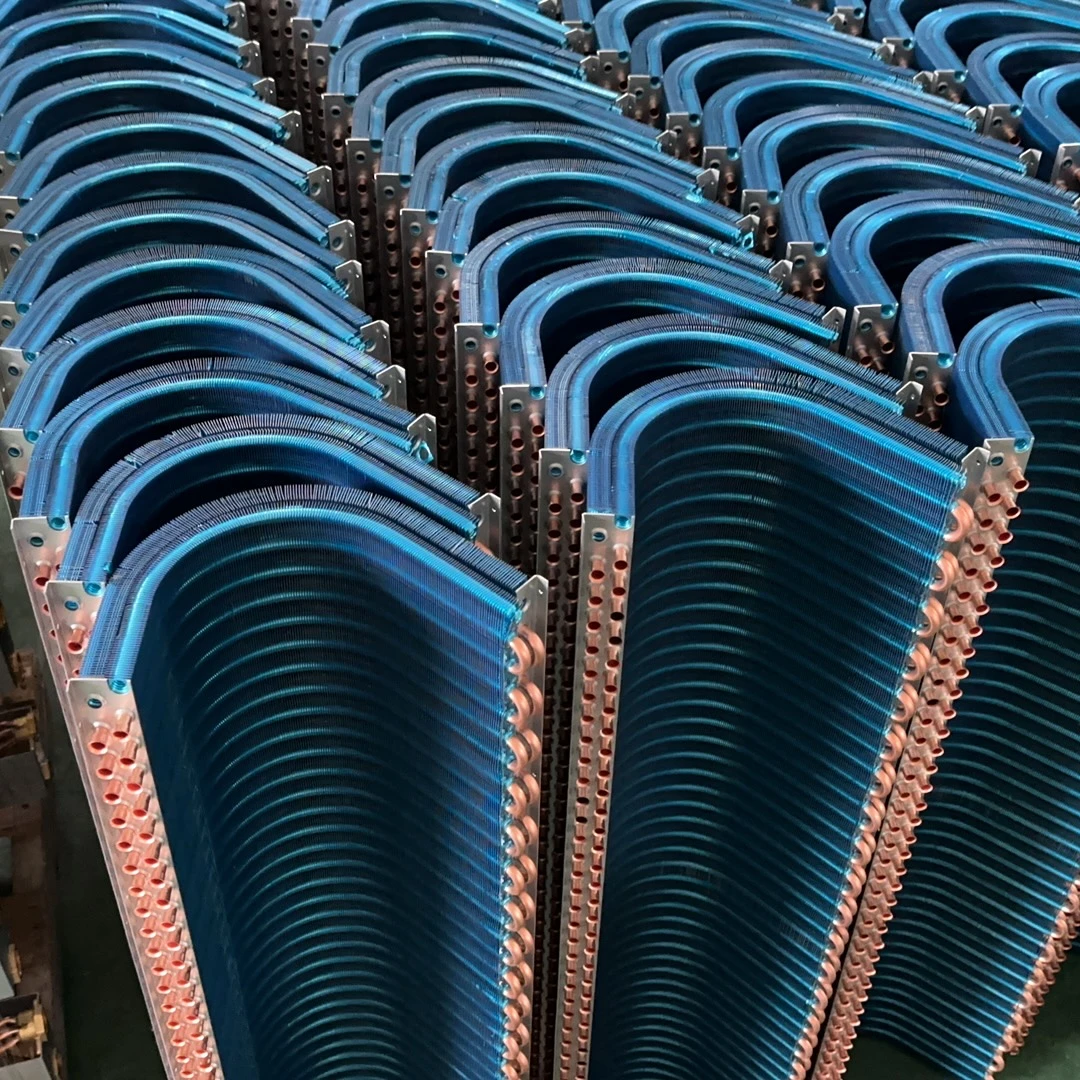

The use of aluminium in these heat exchangers is a very good thing. A – For one, aluminium is a superb conductor of heat and electricity,… Aluminium heat exchangers, with the help of this property, can easily conduct heat and do their job very efficiently. This movement of heat will assist to keep the temperature in spaces warm or cool as desired. And, aluminium stays rust free so that it can still work even in tough places where they might get hot or wet and dirty.

Aluminum: Aluminum is also an ideal option for the high temperatures. It can withstand heat of 400° C, and that is very hot! It provides great immunity to heat which makes it very stable. As a result, it can be used where other materials crack or fail under severe conditions.

By using aluminium heat exchangers, you can evidently save not only money but energy at the same time. This can reduce the amount of energy needed to heat or cool different spaces by moving heat around efficiently. This alone helps to save on the energy bills, but also a help for our planet since we do use less duh.

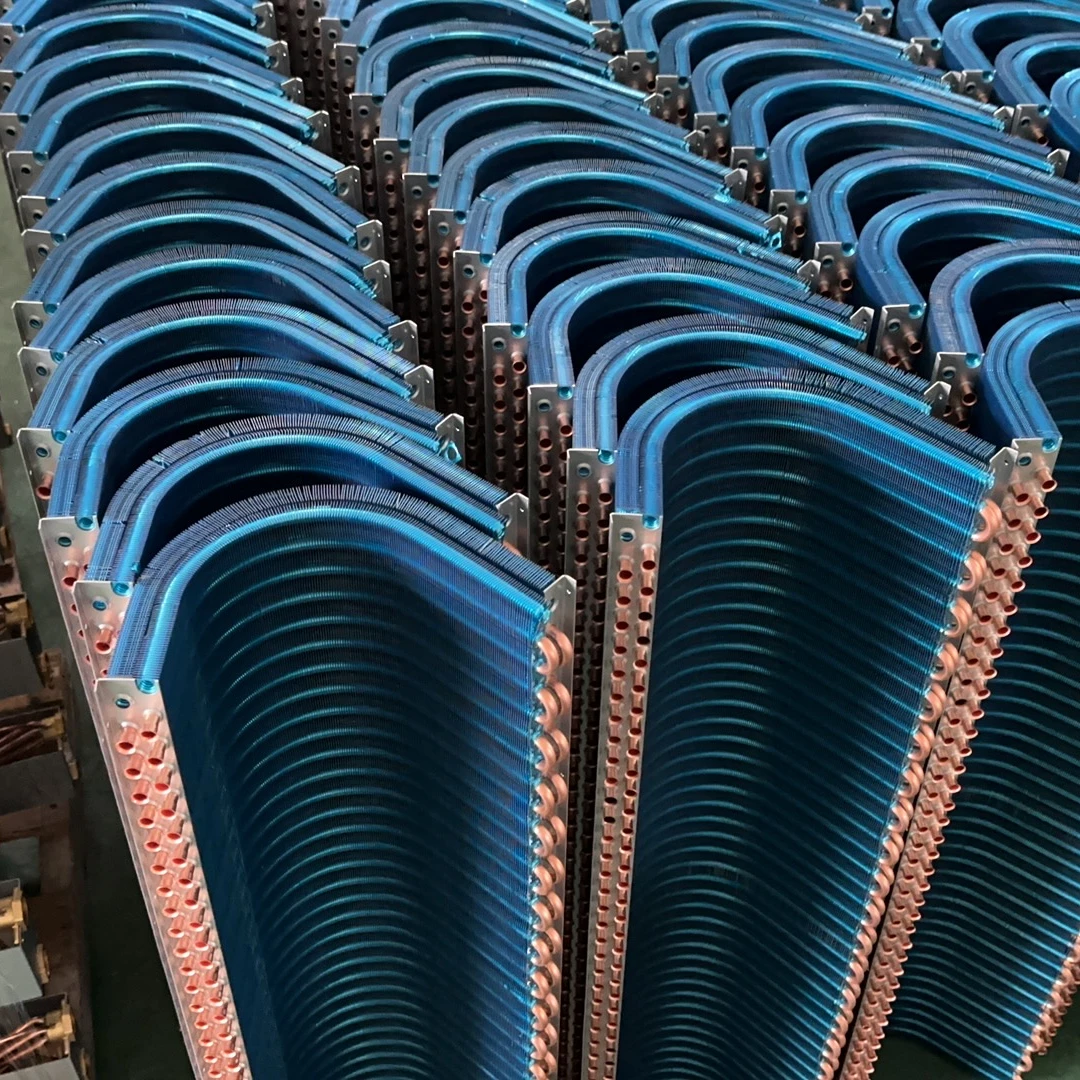

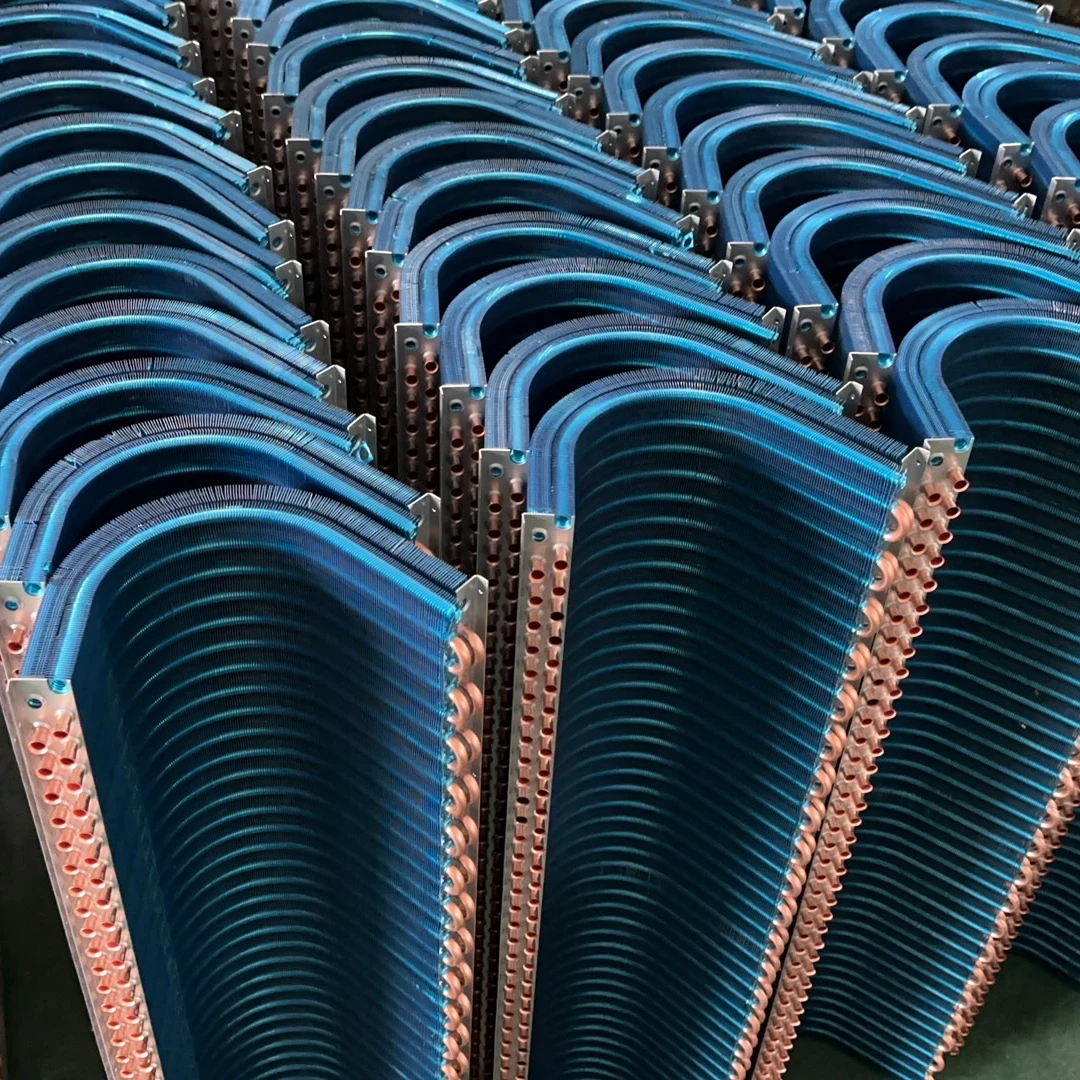

Additionally, aluminium heat exchangers come equipped with intelligent designs to ensure better performance. The newer and more modern aluminum heat exchangers are able to maximize their effectiveness by using the up-to-date technologies. Different geometries, sizes and shapes of tubes can be used in the same design to improve heat transfer. Some of them may even have fins or lumps on the metal surface. These fins and bumps expanded the surface area, which assisted moving heat swiftly.

SHUANGJUN Electric Appliance Company. which founded 2007 grown aluminium heat exchanger reputable company specializes manufacture refrigeration equipment. Through continuous development advancement over past two decades, now are becoming top machine manufacturer solution provider HVAC Refrigeration industry.

aluminium heat exchanger 3D design softwares, heats transfer simulations other techniques assist each customer design equipment that matched maximal efficiency. offer wide range customizations order meet demands customer. One-stop solutions offered scratch, turnkey projects executed.

aluminium heat exchanger consulting staffs years experiences both after-sales pre-sales. sales consultants quickly responds inquiries. They able tailor products that need within shortest possible times offer most competitive prices transactions.

offerings include heat exchangers well as air aluminium heat exchanger indoor units. also offer air conditioning systems. products suitable many different scenarios such commercial, industrial bathrooms kitchens.